E-Stream at Handelsblatt: Future-oriented reusable battery storage technology made in Germany

7. März 2021

BATTERY TECHNOLOGY MADE IN GERMANY

The energy turnaround as well as electromobility promoted by the German government depend very much on innovative battery storage technology. The EU regulation, in force from 2021, which governs the EU-wide average CO2 emission target for the new car fleet of individual car manufacturers, specifies a value of 95g/km. If this target is not reached, massive fines will be due for the manufacturers. For this reason, European automakers are making great efforts to launch CO2-neutral electric vehicles.

Almost all European manufacturers are using large so-called prismatic cells for this purpose. This leads to a shortage of this battery type on the world markets. At the same time, prismatic cells are also used for industrial battery storage systems or residential storage. The American manufacturer Tesla uses cylindrical cells instead of prismatic battery cells. Tesla as well as E-Stream see cylindrical cells as having unbeatable advantages over prismatic cells in parameters such as energy density, thermal management, safety, performance, flexibility, sustainability and cost.

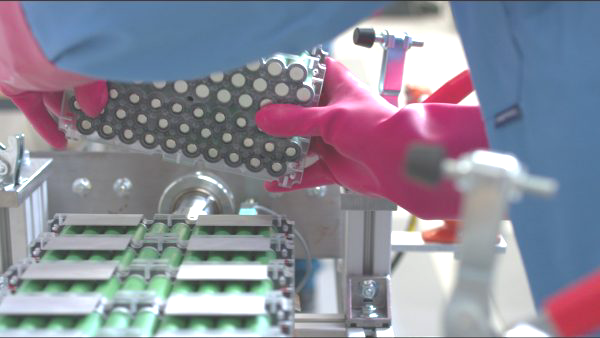

The shape utilization factor for cylindrical cells can reach up to around 94 percent - in contrast, a maximum shape utilization factor of 60 percent is available for prismatic cells. E-Stream expects cylindrical cells to remain superior to all other cell types for at least another decade. In addition, E-Stream has developed an innovative packaging system for cylindrical cells. This system achieves the highest energy density compared to competitors. It is a lightweight construction in which the cylindrical cells can be arranged as compactly as possible. As a result, the e-stream battery storage systems have an enormously high energy density. This means a greater range for electric vehicles.

The higher power density of the cylindrical cells in the smallest possible installation space also allows small electric vehicles to be driven dynamically. The E-Stream battery storage systems feature high-voltage capability of up to 1000 volts and also a very high fast charging speed of 20 to 80 percent SoC in about 15 minutes. Low-resistance interconnect technology provides high electrical efficiency and, consequently, lower heat losses and higher power density at both the cell and module levels. Unlike prismatic cells, E-Stream's battery storage has virtually unlimited flexibility for electrical parameters such as capacity, voltage, energy or performance.

Battery technology - made in Germany

The cylindrical cells used by E-Stream offer a high degree of safety. On module and system level there is a significantly reduced risk compared to prismatic cells of a Thermal Runaway. Due to the use of a large number of small battery cells, a Thermal Runaway would result in a time-delayed fire propagation. Compared to prismatic cells, cylindrical cells have a significantly lower amount of energy per individual cell - by a factor of 27. The hermetically sealed housings of cylindrical cells also offer special protection. The system availability of the battery module in the event of a cell malfunction should be emphasized. The defective cell is disconnected from the network, while the drive train remains functional.

The thermal properties of cylindrical cells are ideal: they enable the use of efficient, cost-effective and space-saving thermal management solutions. Cylindrical cells are much easier to cool and, if necessary, to heat due to low thermal resistance and lower heat capacity. Advantageous thermal behavior of cylindrical cells in combination with E-Stream's innovative cell connection technology avoids hot spots, so that heat flow and heat distribution are optimal. This means that cooling is much more cost-effective with cylindrical cells than with prismatic cells - at the same time, the charging process can be made much faster.

E-Stream's battery storage systems follow the principle of Lego bricks. They offer almost unlimited flexibility in terms of installation space, capacity and voltage. This is a huge advantage, especially in electromobility. Space problems combined with insufficient energy efficiency represent a negative performance factor here that should not be underestimated.

The service life of a battery depends mainly on the cell chemistry, the electrical utilization and the quality of the cell connection technology. E-Stream's technology offers innovative gentle cell connection technology without thermal processes and avoids pre-damage effects during the production of battery modules.

Sustainability is an important issue in the production and finalization of battery modules: When the end of cell life structure is reached, E-Stream's battery storage system can be refurbished and individual cells from the composite can be replaced. Thus, end-of-life cells from E-Stream's automotive packs can be easily disassembled and used in other energy storage applications, giving them a second life. E-Stream's innovative technology enables a second life for both the individual cells and all other system components. In addition to the publicly discussed sustainability aspect, this is also a decisive cost advantage. Simple, fast and industrial production of E-Stream's battery storage systems offers cost and time advantages.

In recent years, German industry has been accused of neglecting the development of battery storage capacity and thus also the possibilities of electromobility. With E-Stream, there is now a German company that offers solutions to all the important questions surrounding the all-decisive performance of battery storage systems.